- contact@armorinox.com

- +33 (0) 297 22 62 63

Water Pasteurization & Chilling Solutions for Hot dogs

Armor Inox is the leader for fully continuous automated pasteurizing and chilling solutions.

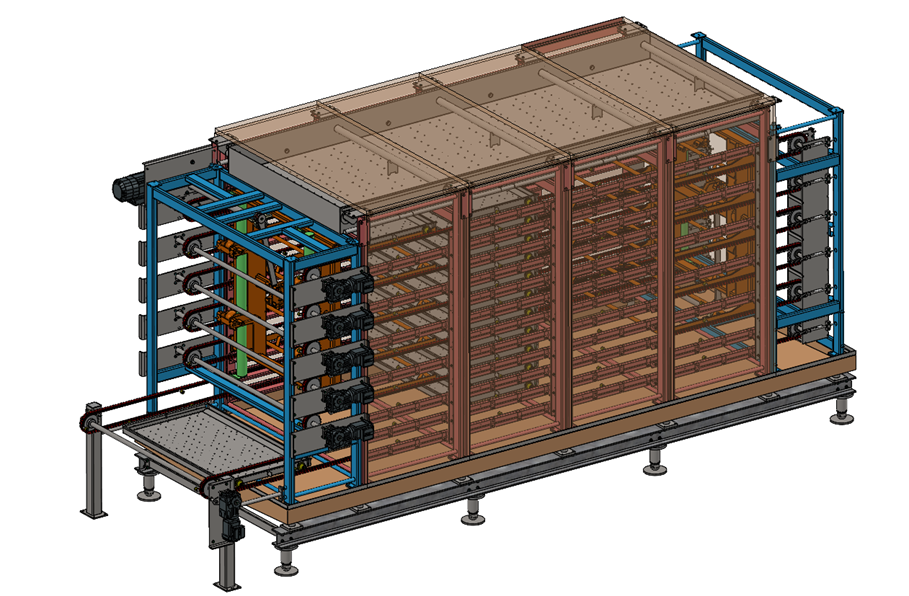

The Flowmatix™ system delivers a continuous product flow while having the flexibility of a throughput of 200 to 2,000 kg/h with the lowest manufacturing costs in the market.

The Flowmatix™ system is an integrated pasteurizer and chill process that is fully automated from loading the products to unload before packing.

Flowmatix™ system combines high capacity, optimal production performance and high productivity. Best control and process repeatability for energy savings. Full process traceability for maximum food safety operations.

Flowmatix™ is a patented semi-immersion pasteurizing and chilling process with continuous circulation of water and recycling of hot and cold fluids there by significantly reducing energy consumption.

Flowmatix™ system significantly improves cooking yields thanks to optimized heat exchange with homogeneity and precise temperature regulation, guaranteeing the fastest pasteurizing and chilling time.

Automation of the loading and unloading systems are specially designed for each customer’s needs, enable on demand solution from loading to unloading products.

Fully automated, advanced solution to pasteurize and cook products

Copyright 2026

Armor Inox - The Middleby Corporation